As global temperatures and sea levels continue to rise, the urgency of individual and collective environmental responsibility has never been greater. The cosmetics industry, in particular, must play its part in minimising its impact on environmental pollution.

Recently, there has been a noticeable shift in this direction, with many companies investing in sustainable practices and systems aimed at reducing their environmental footprint across various stages of the production chain. There are no specific refillable cosmetics regulations but rather guidance clarifying the applicable regulatory framework.

Research and Innovation: How Cosmetics Companies Evolve Toward Sustainability

In the cosmetics sector, governed by Regulation 1223/2009, sustainability requires careful attention to raw material selection, packaging, the environmental impact of production, and transportation. Achieving sustainability is a complex process, marked by several challenges. The primary goal is to reduce emissions and resource consumption while maintaining environmental balance.

A key approach begins with raw material selection. Cosmetic companies are increasingly turning to natural or plant-based ingredients, moving away from petrochemical sources. This shift is driven not only by consumer appeal but also by a genuine need for environmental sustainability and the ethical treatment of workers involved in production.

The Future Challenges of Sustainable Cosmetics

In terms of packaging, the focus is increasingly on reducing the amount of packaging, using recyclable materials, and providing consumers with clear information on how to efficiently dispose of each component.

The market is also encouraging a culture of consumer awareness, promoting the responsible use of cosmetics and proper disposal of waste. Additionally, the use of gases in cosmetics has significantly decreased, with more frequent adoption of mousses and no-gas spray systems, where product delivery relies on mechanical pumps rather than propellants.

Regulations and Definitions: A Necessary Step for Sustainable Cosmetics

In the wide-ranging landscape of sustainability efforts, it is important to recognize that some companies in the cosmetics market, whether knowingly or not, engage in “Greenwashing.” This practice misleads the public: “the misappropriation of environmental virtues aimed at creating a green image” as defined by the European Commission. We explored this issue in depth in our article on Greenwashing, which refers to European Directive 2024/825

To date, sustainability can be communicated to consumers in various ways: through product certifications (e.g., the Nordic Swan, which reflects strong environmental concerns in Northern European countries), process certifications (such as ISO 14001, which sets the requirements for an environmental management system), or by using methodologies like the Life Cycle Assessment (LCA), which evaluates environmental performance based on two ISO standards.

This means that simply using natural or plant-derived raw materials is not enough to claim sustainability.

There are numerous strategies available, and in the absence of clear guidelines—challenging to establish due to business complexities—it is up to companies to communicate their sustainability efforts transparently. This includes not only sharing the results already achieved but also outlining future goals, ensuring clarity and avoiding misunderstandings.

Understanding Microbiological Risks in Refillable Cosmetic Products

In recent years, growing awareness of climate change and waste management has led to an increased demand for products with more “sustainable” packaging, including refillable cosmetics.

Refillable products come in various forms: transfer refill, where the product is transferred from one refill (single or multi-use) to another container or dispenser. This includes loose or “on tap” cosmetics, cosmetics with refill bags, and those in wall dispensers, such as hand soaps in public bathrooms or shower products in hotels and spas.

Another type is the replacement refill, which provides a sturdy, reusable packaging that houses a smaller container, such as a jar, bag, or capsule, which remains sealed until it’s time to recharge.

While refillable cosmetics offer environmental benefits, they present technical challenges, particularly regarding the risk of microbial contamination, safety, packaging integrity, functionality, and product stability.

Critical Factors for Microbiological Risk in Cosmetics

Microbiological contamination of a product can occur due to environmental or human contact during various stages: the production process, handling and storage, or use.

When assessing the microbiological risk of refillable cosmetics, it is essential to consider the various scenarios that are “reasonably foreseeable,” as outlined in the Safety Assessment of a cosmetic product. Each scenario presents different microbiological risks, and numerous variables must be taken into account. The most critical factors include the type of packaging, how it is cleaned, the type of refill, and the product’s usage.

Type of Packaging of Refillable Cosmetic Products

The packaging that will be filled can be the “original” one provided by the brand or one chosen by the consumer, whether new or previously used, for example, to contain cosmetics, food, or household cleaning products. Depending on its shape, components, and size, packaging can protect the product more or less effectively. From a technical perspective, it can be challenging for refillable cosmetics to combine functionality, aesthetics, and safety.

Washing refillable cosmetics containers

The washing phase of the container before filling, if required, is a critical factor. In the most difficult-to-dry areas, such as pumps and nozzles, water or residues from detergents or other substances (including organic materials or biofilms) may remain, which can impact microbiological safety.

Charging type for refillable cosmetics

The microbiological risk changes depending on whether the refill is conducted by the consumer, a point-of-sale operator, or if it involves transferring the product to a container or using a “replacement” type.

Product use

Refillable cosmetics can also have very different applications. Some are marketed for home use by a single consumer, while others are installed in humid environments and used repeatedly by different consumers, such as cosmetic dispensers in public places.

Reduction of the Microbiological Risk of Refillable Products

Given that microbiological criticalities can arise from various factors, reducing the microbiological risk of refillable cosmetic products requires a multifaceted approach.

Formula

Intrinsic characteristics, such as the presence of preservatives, pH value, free water content, and specific ingredients, can influence a product’s resistance to microbial contamination. The preservative system, if present, must be robust enough to withstand repeated microbiological stress. Unfortunately, identifying an optimal preservative system can be challenging, as many preservatives considered safe by the SCCS (Scientific Committee on Consumer Safety) are often not used because they do not align with the demands of the “green” market. See the latest version of the Notes of Guidance for the evaluation of the safety of cosmetic ingredients.

Packaging

Packaging serves not only to attract consumers but also to protect the product and minimise its exposure to the environment and users, significantly contributing to the reduction of microbiological contamination risk. The more consumers interact deeply with the product, the higher the microbiological risk becomes. The format of the packaging also plays a role; larger containers are used for longer periods, which increases the number of microbial stresses they endure.

Additionally, the presence of moisture and microorganisms in the environment raises the contamination risk if the packaging does not effectively protect the product. Wall-mounted dispensers with top refill and a dispensing lever located in public toilets are among the products with the highest microbiological risk, while products with replacement refills or closed automatic dispensers (which do not allow users to open them from above) present a lower microbiological risk.

The parts of which the container is made—such as nozzles, pumps, bags, caps, and applicators—and the ease of opening are crucial, as they influence the degree of protection for the product, the ease of cleaning operations, and the potential for tampering. In particular, applicators that remain in contact with the product, such as mascara brushes, metal spheres, and sponges, can pick up microorganisms, moisture, sebum, and particles, concentrating them in the product and leading to a higher risk of contamination and infection.

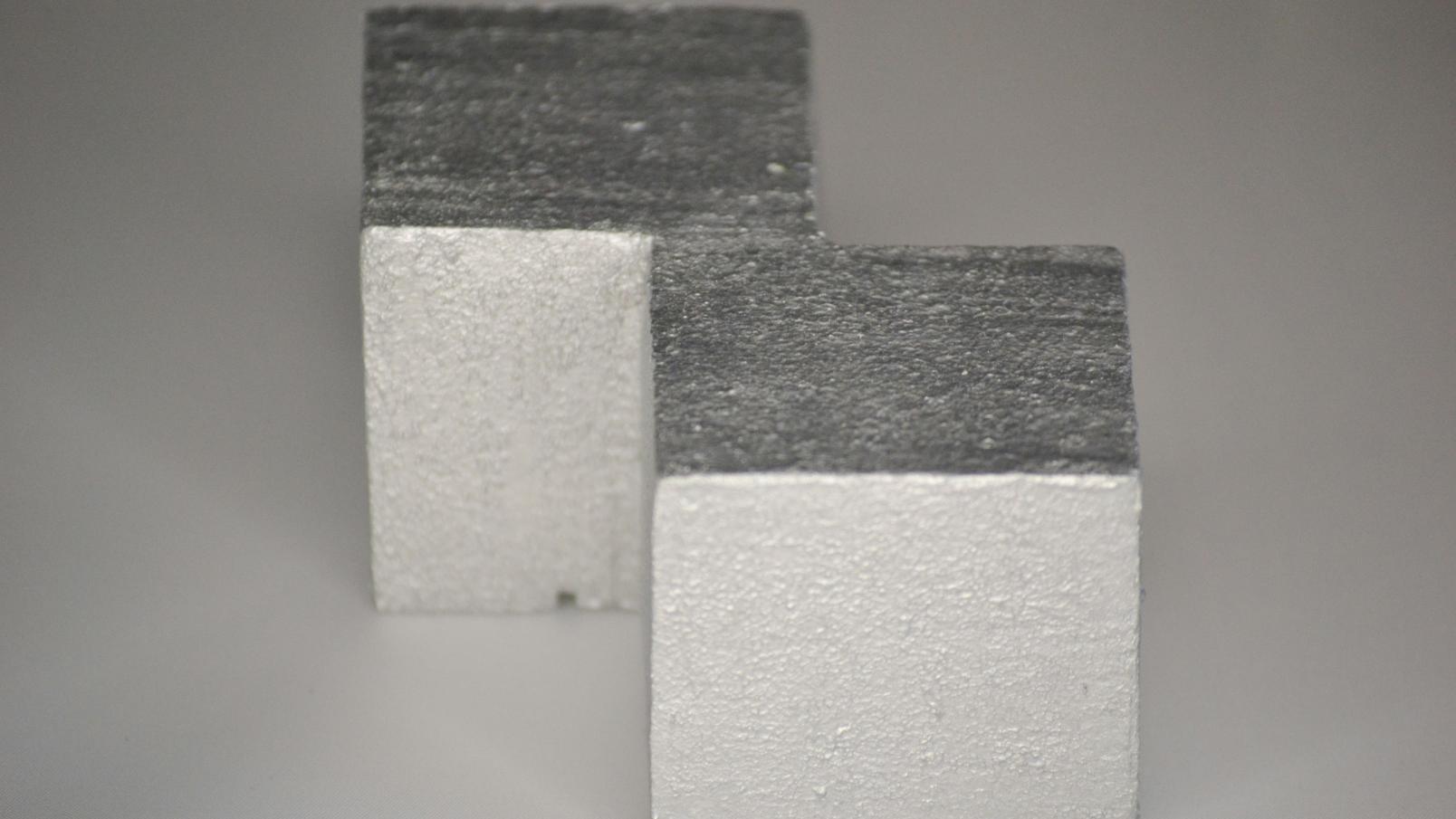

Finally, the materials used for packaging should not be underestimated. Natural materials, such as fibres, sponges, and wood, are highly sought after in “sustainable” products; however, they also pose a greater microbiological risk. Even when treated and decontaminated, these materials can have pores, irregularities, organic substances, and residual moisture that promote microbial growth. You can refer to our article on cosmetics packaging regulations to better understand what is at stake.

Development of Adequate Cleaning Protocols for Refillable Cosmetics

As with all cosmetic products, the hygiene of the production process is essential to reduce the risk of contamination. To produce refillable formats, it may be necessary to modify systems, equipment and protocols. In particular, if washing is planned before filling the primary container or dispenser, it is advisable to validate the procedures and establish methods and frequencies for cleaning.

Laboratory Tests for the Safety Evaluation of Refillable Products

Given the microbiological fragility of refillable cosmetic products, classic tests for microbiological evaluation may not be suitable. Therefore, it is recommended to conduct more rigorous tests that simulate consumer use.

The choice of tests should be made on a case-by-case basis, considering the product, its criticalities, and its microbiological risk, but general guidelines can be provided. For assessing microbiological stability, repeated and closely spaced inoculums over time can better simulate the microbiological stress that some refillable products experience.

It is advisable to conduct challenge tests on a wider range of microbial species than those required by ISO 11930 or the European Pharmacopoeia and to establish stricter acceptability limits than those indicated in Criterion A.

Additionally, the information from these tests can be complemented with microbiological analyses on aged and in-use products. If a washing and filling system is developed alongside the product, it must also undergo microbiological testing.

Packaging compatibility and suitability testing should be more rigorous, as both the primary refillable cosmetic container and refill containers must be robust and protective enough to endure multiple manipulations.

In addition to mechanical resistance tests of the packaging, stricter stability tests are recommended, using higher temperatures, varying humidity levels, and prolonged exposure to light, evaluating both the release of substances from the packaging into the product and the absorption by the formula. Short-term accelerated testing may not be predictive.

If the container is designed to be washed, the compatibility of the packaging with the washing system, different detergents, and repeated operations must be thoroughly tested.

Cosmetovigilance

In recent years, numerous types of refillable containers have been developed, featuring various designs and materials. For many of these products, being relatively new, there is a lack of post-market data regarding their behaviour.

Unlike traditional packaging, which has substantial data from literature and business experience, refillable options are often uncharted territory. This scarcity of information complicates the ability to make accurate predictions about the product’s susceptibility to microorganisms and its overall stability.

Consequently, in addition to conducting more in-depth and rigorous tests on the product before market introduction, it is crucial to implement a robust and careful cosmetovigilance system.

Establishing Safety Criteria for Refillable Cosmetics

As of now, there are no defined, specific criteria to determine the safety of refillable cosmetic products, nor are there established guidelines in this area. A crucial aspect to consider is what the Safety Assessor will take into account when evaluating the product.

Do you have any concerns about the microbiological safety of your refillable product? Contact us, and we will be happy to assist you in evaluating your product to ensure its safety.