The focus on environmental sustainability continues to grow, involving both companies and consumers. One particularly pressing issue is the impact of packaging, which accounts for a significant proportion of waste released into the environment.

Many companies are actively working to reduce their environmental footprint by limiting packaging and making it more sustainable for product transport. In this context, sustainability certifications serve as a valuable tool both operationally and in communication.

Recognition from accredited third parties confirms that efforts to improve the environmental impact of packaging are genuine and effective.

Certifications provide a transparent way to communicate green credentials and help distinguish a company in the market. Furthermore, the process of obtaining certification guides businesses in adopting genuinely sustainable production methods and packaging choices.

Sustainability Certifications

Let’s take a look at some of the main environmental certifications that companies can adopt.

ISO 14001 – Environmental Management System

ISO 14001 certification confirms a company’s voluntary adoption of an environmental management system designed to minimise the negative impact of its activities and promote continuous improvement in environmental performance.

This widely recognised and respected certification sets out the requirements for an effective environmental management system. To achieve it, a company must conduct a comprehensive initial environmental analysis to identify the environmental aspects and impacts of its operations.

Interventions and projects may also involve the management of packaging materials and processes, including the adoption of more sustainable materials or packaging methods that reduce waste.

Based on this analysis, the company establishes an environmental policy with concrete commitments to improvement. These commitments translate into measurable objectives and specific targets, supported by well-structured environmental management programmes.

Periodic internal audits must also be carried out to ensure the correct implementation of the environmental management system.

Obtaining ISO 14001 demonstrates a company’s structured commitment to environmental sustainability, following internationally recognised standards.

EN 13432 and EN 14995 – Biodegradable and Compostable Packaging: What are the Differences

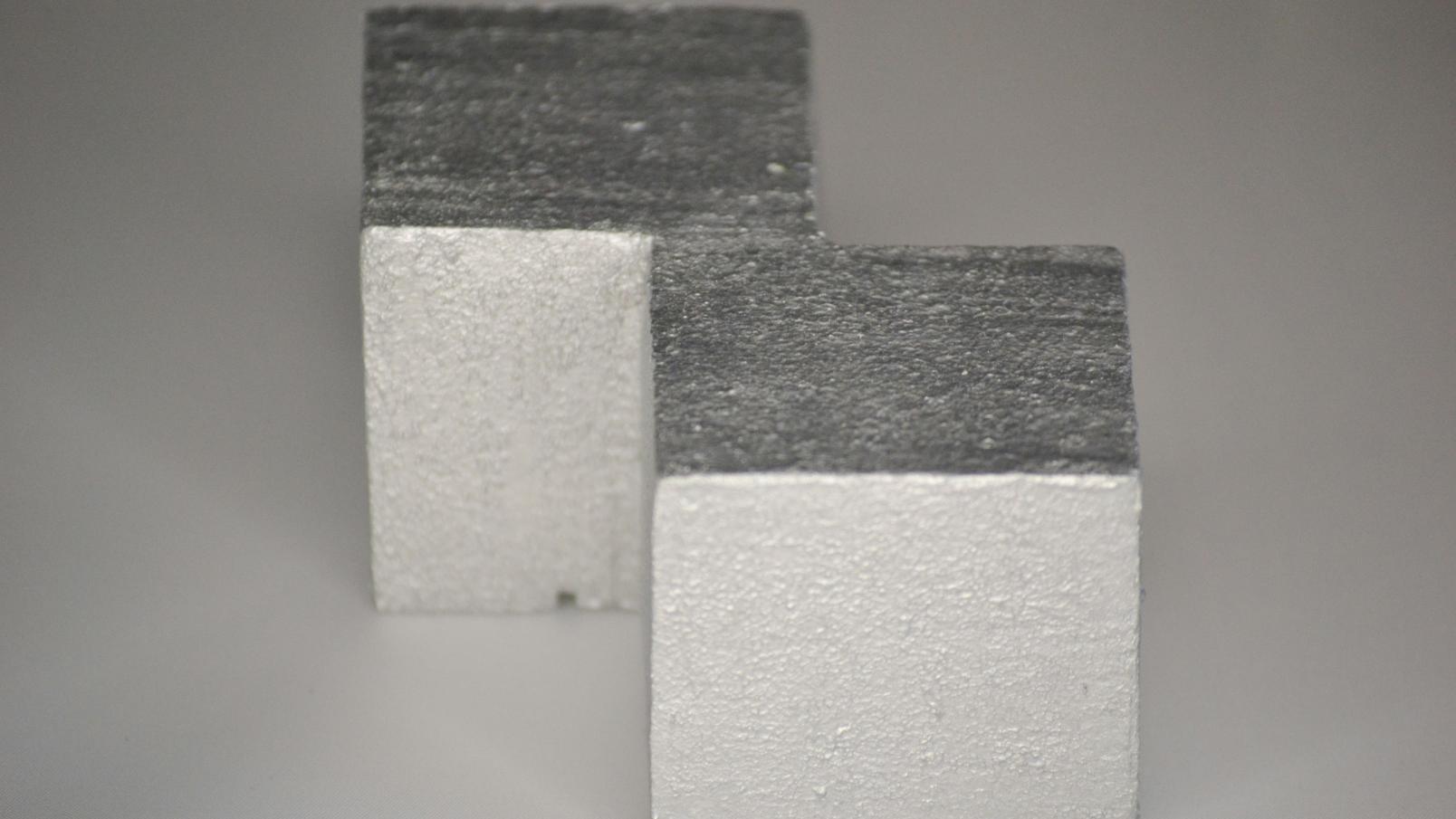

With growing emphasis on sustainability, many companies are adopting compostable and biodegradable packaging solutions. However, the distinction between compostable and biodegradable packaging, their required characteristics, and the relevant regulations are not always clear.

The Characteristics of Biodegradable Packaging

Packaging is considered biodegradable when it naturally decomposes at the end of its life cycle without causing environmental harm. These materials can be broken down by living organisms into monomers, producing natural substances such as water and gases.

Current legislation, which will be examined below, sets specific timeframes within which packaging must decompose to be classified as biodegradable.

Reference Legislation on Biodegradable Packaging

Biodegradable packaging is subject to strict regulations and must meet defined decomposition timelines. According to the European standard EN 13432:2002, packaging is considered biodegradable only if 90% of its material undergoes biodegradation within six months. However, biodegradable plastics cannot be disposed of with organic waste and must be processed separately.

The Characteristics of Compostable Packaging

Compostable packaging follows a more complex decomposition process, as it must undergo treatment through composting, which requires specific climatic and environmental conditions.

Natural elements, consisting of polymers of varying complexity, are broken down using specialised machinery to produce a final substance called compost. This compost can then be used in various industries, including agriculture and floriculture.

Like biodegradable packaging, compostable packaging provides protection and durability during transport, mimicking the properties of traditional plastic while significantly reducing or eliminating environmental harm.

Reference Legislation on Compostable Packaging

Current legislation EN13432 states that a product is considered compostable if it degrades by 90% within six months in an environment with high concentrations of carbon dioxide or within three months when in contact with organic materials.

Additionally, the material must not interfere with the timing or quality of the composting process and must meet specific requirements for pH, salt content, phosphorus, nitrogen, and magnesium levels.

Compostable Packaging: What the Legislation Says

Compostable packaging is becoming increasingly popular for its ecological and sustainable benefits. Made from materials that can be disposed of with organic waste, it fully degrades within a short period without leaving harmful residues in the environment.

It can also be recovered and transformed into new organic resources, helping to reduce environmental impact. This innovative and environmentally friendly solution supports waste reduction and the conservation of natural resources.

The Importance of Compostable Packaging

Compostable packaging is an advantageous solution for companies looking to combine efficiency, sustainability, and competitiveness in their production processes, as it allows them to:

- Save resources and reduce waste – Made from renewable raw materials sourced sustainably, compostable packaging has a shorter life cycle than traditional plastics. It can be disposed of with organic waste, preventing contamination of recycling streams.

- Differentiate and enhance their brand – While protecting and preserving products, compostable packaging also appeals to environmentally conscious consumers. As awareness of sustainability grows, consumers increasingly prefer products with eco-friendly packaging. Compostable packaging demonstrates a company’s commitment to responsibility and innovation, helping it stand out from competitors and improve its reputation.

- Comply with regulations and quality standards – Compostable packaging must meet specific criteria certifying its biodegradability and compostability. It also ensures the quality and safety of the products it contains, preserving their organoleptic properties such as taste, aroma, freshness, and consistency.

European and Italian Legislation on Compostable Packaging

The regulatory framework for compostable packaging consists of:

- European Directive 94/62/EC on packaging and packaging waste, which establishes general criteria for the prevention, reuse, recovery and disposal of packaging;

- European technical standard EN 13432, the first-ever standard on compostability, first published in 2000;

- European technical standard EN 14995, which specifies the requirements and procedures for determining the compostability or anaerobic treatment of plastics with reference to their biodegradability, disintegration during biological treatment, effect on the quality of the compost derived from them.

EN 13432 is voluntary and defines the requirements for packaging recoverable by composting and biodegradation, the tests and criteria to be followed for their evaluation on the basis of which the final acceptance of the packaging will be decided.

There are other UNI technical standards that regulate the coding of packaging to facilitate its collection, recovery and recycling. These include:

- UNI EN ISO 14021 which identifies plastics;

- UNI 1043-1 for the identification of polymers not included in Decision 129/1997 (which establishes the criteria for the identification of packaging materials on the basis of 94/62/EC);

- UNI 10667-1 concerns the identification and recognition of polymers from recycling;

- UNI 11469 for packaging made of composite materials.

Characteristics of Compostable Packaging EN 13432:2002

A material or a product made with it, in order to be defined as compostable in accordance with EN 13432:2002, must have the following characteristics:

- biodegradation at least 90% after six months, transforming into carbon dioxide, water and biomass due to the action of the microorganisms present in the compost;

- disintegration after 12 weeks, the biomass resulting from decay must be made up of at least 90% fragments smaller than 2 mm, and must not have a negative influence on the composting process;

- quality of the compost: the material must not cause chemical, physical and biological alterations to the final compost (compatibility of the process), and the content of heavy metals and other chemical substances must remain below the legal limits established by the standards indicated above.

These characteristics must be verified by means of special laboratory tests, the metrics and procedures of which are indicated in the text of the standard itself.

Certification and Labelling of Compostable Packaging

Materials and products that comply with the UNI EN 13432 standard can obtain certification and related labelling, as the standard also includes a series of marking requirements for compostable packaging.

The certification information must be clearly visible, indicating compliance with the legislation. It should detail the composition of the product, provide instructions for use, and include the logo of the accredited body or organisation that carried out the verification process for issuing the certificate of compatibility.

In Europe, the most widely used certification standard based on this legislation is the OK Compost INDUSTRIAL certification, issued by TÜV AUSTRIA. This certification guarantees that the material or product can undergo the composting process in an industrial plant, in line with the conditions and times specified by the standard.

Additionally, there is the OK Compost HOME certification, which verifies the ability of packaging to degrade in a home composter or in an environment at room temperature, indicating home compostability.

Biodegradable or Compostable Packaging: Which is the Most Sustainable Choice?

Whether we are talking about biodegradable or compostable packaging, both are sustainable and environmentally friendly choices that help limit the production of greenhouse gases and do not harm ecosystems, unlike traditional plastic.

While all compostable elements are biodegradable, the reverse is not necessarily true. Compostable packaging has the advantage of breaking down into a fertilising substance, contributing to the land by providing natural and biological components that nourish the earth.

Recycling costs are lower for biodegradable plastic, as it decomposes under a variety of environmental and climatic conditions over time. In contrast, the process of treating compostable packaging requires specialised machinery and facilities.

ISO 17088 Certification

ISO 17088 is a relatively recent certification, published in 2021, specifically focused on paper packaging intended for food contact.

To obtain this certification, a company must demonstrate that it uses only paper and cardboard that comply with specific international standards relating to the components present, as well as the inks and glues used. These must meet stringent limits regarding migration and potentially hazardous substances.

The certification guarantees that harmful substances will not transfer from the paper packaging into the food. Therefore, the ISO 17088 standard provides an additional layer of safety, complementing the certifications already required for food contact materials.

LCA – Life Cycle Assessment – ISO 14040 and ISO 14044

Life cycle assessment (LCA) is a comprehensive tool for quantifying the environmental impacts of a product during all stages of its existence.

ISO 14040 and ISO 14044 define in detail the principles, methodology and requirements for conducting an LCA study. The aim is to identify and compare the impacts associated with different solutions, to guide design and production choices towards maximum environmental sustainability.

An LCA study involves the following steps:

- definition of objectives and scope;

- inventory analysis, with collection of data on system inputs and outputs;

- assessment of impacts in relation to parameters such as global warming, resource consumption, toxicity…;

- interpretation of the results.

For packaging, for example, different alternative materials, production processes, end-of-life options can be compared. Life cycle assessment thus provides data-backed information to identify solutions with the lowest environmental impact.

Other Sustainability Certifications for Packaging

In addition to the certifications already mentioned, there are others that may be relevant for demonstrating the sustainability of packaging:

FSC and PEFC guarantee that paper and board come from sustainably managed forests. In detail, FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification) are international certification schemes that guarantee proper forest management according to strict environmental, social and economic standards.

The EU Ecolabel is an eco-label of the European Union that rewards products and services with reduced environmental impact considering the entire life cycle. It can also be applied to some types of packaging.

The ISO/TS 14067 – Carbon Footprint Protocol (CFP) standard: it is the quantification of the CO2 emitted during the entire life cycle of a product, from the extraction of the raw materials necessary for production, to final disposal.

For packaging, the carbon footprint therefore quantifies the impacts in terms of emissions related to all phases of the life cycle: raw material procurement, production, transport, use, end of life.

ISO 14046 – Water Footprint: is the metric for measuring the impact of a product in terms of water consumption and pollution during its entire life cycle. Useful for packaging that uses water in production processes.

The growing interest of companies in improving their environmental impact and obtaining these certifications reflects the increasing awareness of environmental issues among both producers and consumers.

In this context, packaging and packaging materials play a central role in minimising waste and reducing the environmental impact associated with the distribution and marketing of products.

There are many obligations, requirements, and certification opportunities. Discover how to enhance your brand image with our expertise.

Contact us, and we’ll guide you through the registration process.